Bottlebrush Melts and Elastomers

BRUSH MELTS AND ELASTOMERS

Advances in medical implants, tissue engineering substrates, synthetic membranes, and soft robots require materials that are soft, flexible, and tough. To satisfy this unmet technological requirement, our lab has developed a novel materials design platform. Specifically, we utilize precise control of branched polymer architectures to form polymer networks with encoded physical properties and property correlations.

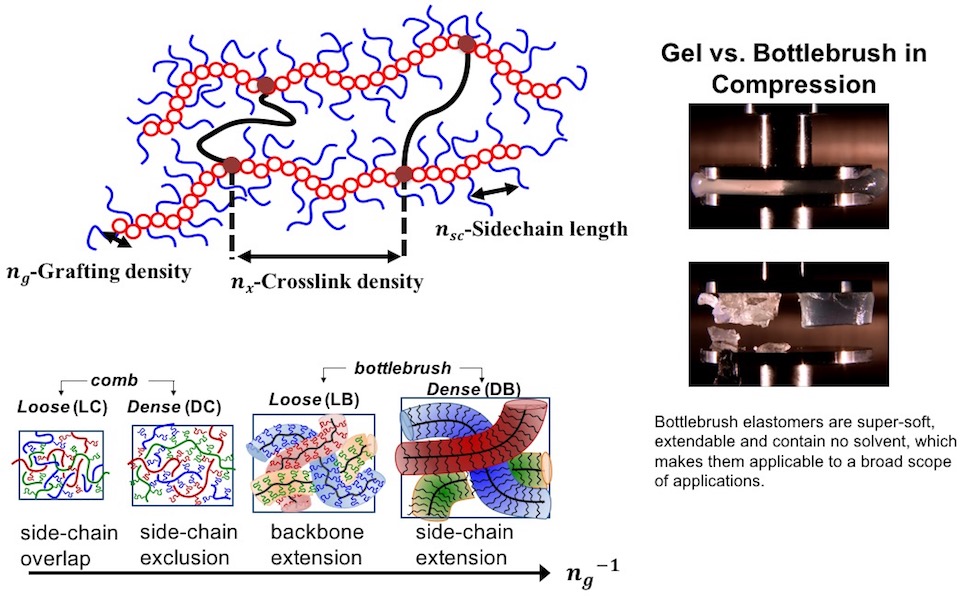

Armed with three distinct architectural handles – crosslinking density, branch density, and branch size – we create materials, without altering chemical composition, that display targeted properties over broad ranges.

Highlights include materials with: (i) softness that is orders of magnitude less than in conventional rubbers, (ii) strength that is orders of magnitude above that in traditional linear elastomers, and (iii) extensibility over ten times the original resting length. These low rigidity, strong strain-hardening behavior, and advanced flexibility will enable mechanically-compatible biological implants, large-stroke robotic actuators, tough/adaptive materials, and biological tissue mimics.

Additionally, these networks possess myriads of free polymer chain ends, allowing for faster molecular motion and higher density of functional groups within the materials, which will enable further application. Architectural control of physical properties is superior to traditional approaches, offering:

- Broad variation of properties without altering chemical composition

- Encoded mechanical performance that mimics specific biological tissues

- Homogeneous and isotropic materials without the complications of composites

- Opportunities for self-healing, programmable, and adaptive functionality

Ultra-Soft Elastomers

Published in Nature Materials researchers in the Sheiko and Rubinstein groups, in collaboration with scientists from the University of Akron, and Carnegie Mellon University, report solvent-free, supersoft and superelastic polymer melts and networks prepared from bottlebrush macromolecules. The brush-like architecture expands the diameter of the polymer chains, diluting their entanglements without markedly increasing stiffness. This adjustable interplay between chain diameter and stiffness makes it possible to tailor the network’s elastic modulus and extensibility without the complications associated with a swollen gel. The bottlebrush melts and elastomers exhibit an unprecedented combination of low modulus, about 100 Pa, high strain at break, about 1,000 percent, and extraordinary elasticity, properties that are on par with those of designer gels.